Turning waste from hard drives into critical resources used in the most efficient wind turbines and electric motors is REEcycle’s passion, the Texas team that won the $100,000 First Place prize at the Third Annual First Look West (FLoW) Regional competition. REEcycle’s process extracts Neodymium and Dysprosium, two precious rare earth elements, essential in manufacturing clean energy technologies, from discarded hard drive magnets. Rare Earth elements are critical to the most efficient wind turbines and electric motors – two technologies that drive the energy efficient future. Retrieving these elements makes the US less dependent on unpredictable foreign sources such as China, the world’s largest exporter of rare earth elements.

REEcycle’s advance was celebrated at an awards event held at the California Institute of Technology on May 7. Along with Second and Third Place winners graphene processor GrollTex and CinderBio, an industrial enzyme innovator, REEcycle shared $160,000+ in prize money and start-up packages that include boot camp scholarships and legal support.

In addition MuTherm took home the $5,000 Transformational Idea Award with an innovation that will boost the safety of the nation’s thousands of miles of gas pipelines. Sponsored by Caltech’s Resnick Sustainability Institute and Draper University (the entrepreneurial educational program founded by venture capitalist Tim Draper) the TIA rewards ground-breaking pre-commercial research.

FLoW http://www.flow.caltech.edu represents the Western Region of the DOE’s National Clean Energy Business Plan Competition (NCEBPC) and is overseen by Caltech’s Resnick Sustainability Institutehttp://resnick.caltech.edu/. The awards event was the culmination of a six month competitive process searching for the untapped clean energy innovation that lies in American university labs. The winning teams from six regions across the country will now participate in the National Competition in Washington D.C., June 11 – 12, 2014.

This year’s winners are:

First Place, $100,000: REEcycle, led by a University of Houston student team, has developed a scalable process for reclaiming rare earth elements Neodymium and Dysprosium from discarded hard drive magnets. Rare Earth elements are used ubiquitously in manufacturing, from cell phones and energy efficient lighting to cracking catalysts for oil refining, and ultra-light materials used in aerospace. The combined Neodymium and Dysprosium market alone, in 2012, was worth over $4 billion, and is expected to grow to $8 billion by 2018.

Second Place, $40,000: GrollTex, http://grolltex.com/about-us/ under a team from the University of California San Diego, is developing a novel process for manufacturing graphene that may be orders of magnitude more cost effective and less wasteful than current methods of production. Labelled the “wonder material” Graphene is 200 times stronger than steel, very flexible and 97.7 % transparent, and is the most conductive material known by weight. GrollTex could find ready markets , ranging from solar panels to large TV displays, once the manufacturing problems are solved.

Third Place, $20,000: CinderBio, http://www.cinderbio.com, a spinout from Berkeley Lab led by a team of UC Berkeley students, uses microbes that thrive in the near-boiling acidic waters of volcanic springs to produce industrial enzymes with unmatched thermal and acid operational ranges. Industrial enzymes are a growing, multi-billion dollar green industry that reduces energy, water, and harsh chemical use while improving process efficiency in many sectors. Potential markets for these enzymes range from cleaning dairy processing facilities ($1B/yr.) to cellulosic biofuels (est. $75B/yr.).Transformational Idea Award, $5,000: MuTherm, http://www.mutherm.com/, emerging from Oregon State University, is developing a microchannel flameless device for powering the wireless sensors that monitor thousands of miles of gas pipelines. The technology reduces the operating and maintenance costs of wireless sensors on natural gas pipelines up to 75% by using the pipeline natural gas to power the sensors instead of the conventional batteries. The market for a device, operating in real time, is substantial: it is estimated that there will be over 200,000 wireless sensors on natural gas pipelines in 2014 with an annual growth rate of 30%.

Recycling Innovator wins at FLoW Rare earth savings could boost US’s energy self-sufficiency

“如果发现本网站发布的资讯影响到您的版权,可以联系本站!同时欢迎来本站投稿!

Magnetic attraction

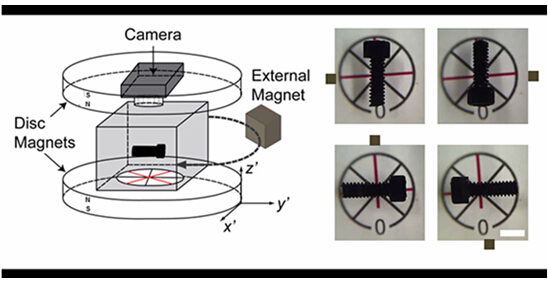

Magnetic attraction Embedded metal in humans could pose a risk

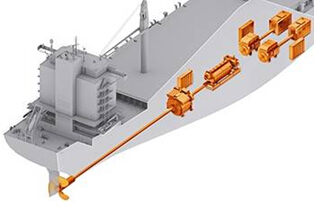

Embedded metal in humans could pose a risk Electric Power Conversion B.V.

Electric Power Conversion B.V. The Switch to Be Acquired by Yaskawa

The Switch to Be Acquired by Yaskawa